Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

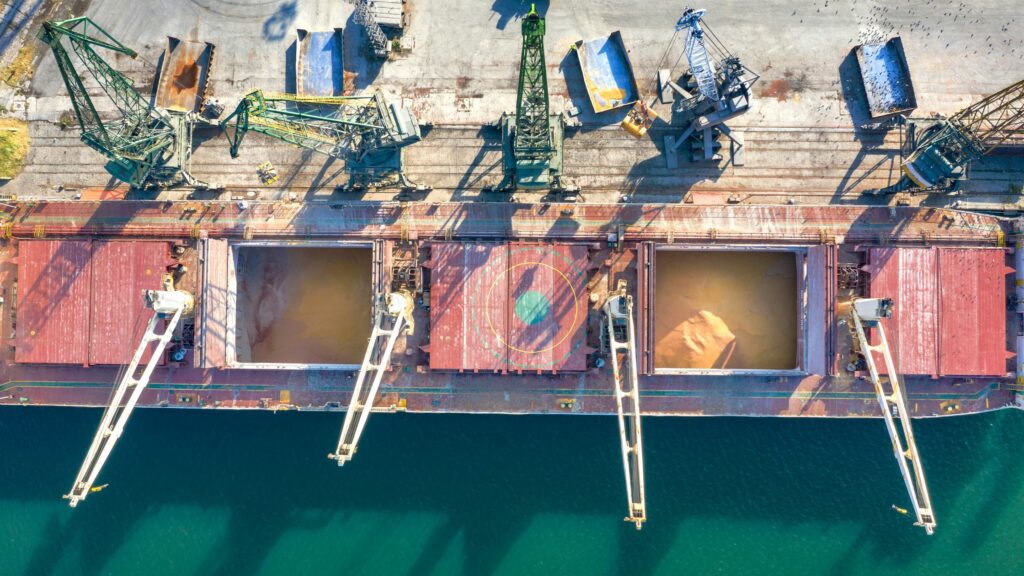

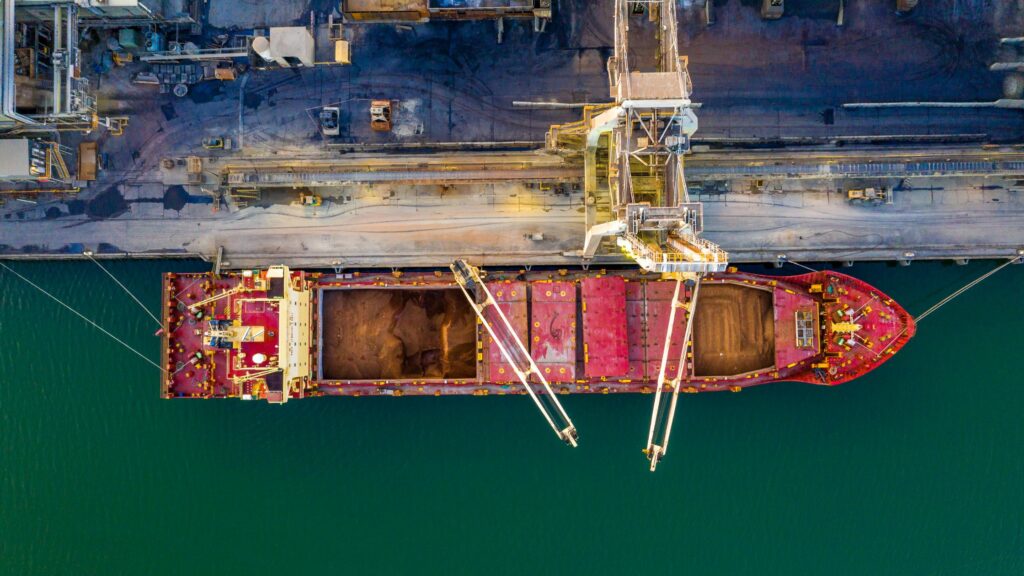

Grain Clean Vessel Standards are vital in bulk shipping and commodity trading. Their focus on cleanliness and adherence to international guidelines ensures grain integrity during transport. This niche within shipping standards is crucial for the industry.

Key aspects include pre-loading inspection, continuous cargo loading monitoring, and specific hold cleaning procedures. These standards provide a framework for ships carrying grain cargoes. Each component, from sweeping and residue removal to using chemicals for stubborn stains, presents challenges, solutions, and compliance implications.

The following sections will explore these elements in detail, highlighting the importance of these standards in ensuring safe, contamination-free grain transport globally.

Grain Clean Vessel Standards are criteria for bulk carriers to ensure the safe, hygienic transport of grain cargoes. These standards prevent contamination and preserve grain quality throughout its journey. Key requirements include:

Adherence to these standards is essential for food safety, market acceptance of grain, compliance with international shipping regulations, and safeguarding the shipping and commodity trading industries’ reputation. The International Maritime Organization (IMO) and various national agricultural authorities set and enforce these standards to uphold the highest grain quality during maritime transport.

Grain Clean Vessel Standards are crucial for maintaining a safe, efficient, and reliable global grain supply chain. Their importance lies in three key areas:

Grain Clean Vessel Standards represent a collective commitment to quality, safety, and regulatory compliance, making them foundational in the bulk shipping and commodity trading industries.

These standards eliminate threats that might compromise grain safety, addressing biological contaminants like bacteria and pests and chemical residues. Stringent cleaning and maintenance protocols reduce contamination risks, safeguarding consumer health and the global food supply chain’s integrity.

Grain Clean Vessel Standards ensure grain’s nutritional value, texture, and quality remain intact during transport. Key measures prevent exposure to moisture and mold, critical for traders and producers meeting global market expectations and successfully trading grain commodities.

The International Maritime Organization (IMO) leads in establishing Grain Clean Vessel Standards, ensuring the safe and hygienic transport of grain cargoes globally. National agricultural and food safety authorities also play a crucial role in adapting and enforcing these standards within their borders. This collaborative approach balances stringent safety measures with practical operational requirements, safeguarding grain quality and preventing contamination in the international shipping industry.

The IMO establishes global regulations for the maritime sector, specifically focusing on Grain Clean Vessel Standards. These guidelines ensure uniform standards for the safe, secure, and efficient transport of grains internationally, equipping the global shipping industry with protocols to prevent contamination and protect grain quality during transit.

National agricultural and food safety authorities ensure local compliance with Grain Clean Vessel Standards, adapting and enforcing global standards to suit their respective countries’ needs. Their efforts ensure that shipping operations adhere to international best practices and comply with national laws and guidelines, ensuring grain cargoes’ safety and quality within their territories.

| Organization | Regulation/Guideline | Description |

|---|---|---|

| IMO | International Convention for the Safety of Life at Sea (SOLAS), Chapter VI | Ensures vessels are loaded, stowed, and secured to prevent shifting and maintain stability. |

| IMO | International Grain Code | Provides requirements for the safe stowage and shipment of grain in bulk, including vessel suitability and loading protocols. |

| National Authorities | United States – Grain Standards Act | Establishes standards for the condition of grain being transported, including quality and cleanliness. |

| National Authorities | European Union – Regulation (EC) No 178/2002 | Establishes the European Food Safety Authority and procedures in food safety, including grain. |

| National Authorities | Australia – Australian Grain Vessel Loading Standards | Specifies requirements for preparing cargo spaces to ensure safe grain transport to and from Australia. |

Bulk cargo logistics plays an indispensable role in global trade and the logistics industry. Its hallmark is the capability to move vast quantities of goods efficiently, offering a unique blend of scale and specialization. This distinct feature positions bulk cargo logistics as a critical sector, facilitating the transportation of commodities that fuel industries and economies worldwide.

The essence of bulk cargo logistics lies in its ability to cater to the diverse needs of dry and liquid bulk goods, from grains and coal to oil and chemicals. Each category of bulk cargo, including Single Dry Bulk, Liquid Bulk, and Break Bulk, is recognized for its specific handling requirements and transportation methods. Single Dry Bulk cargo, for instance, stands out for its efficiency in transporting essential commodities like iron ore and grains, while Liquid Bulk offers specialized solutions for the movement of oil and chemicals.

Delving deeper, the nuances of managing bulk cargo logistics reveal a complex landscape of challenges and strategies. From adhering to stringent environmental regulations to optimizing for cost and efficiency, each aspect of bulk cargo logistics demands a nuanced understanding and approach. The subsequent sections will explore these dimensions in depth, shedding light on the sophisticated world of bulk cargo logistics and its pivotal role in keeping the wheels of global trade and industry turning.

Bulk cargo logistics is the specialized segment of the logistics industry focused on the transportation of large volumes of unpackaged goods. It is divided into two main categories: dry bulk and liquid bulk. Dry bulk includes commodities such as grains, coal, and iron ore, which are essential for various industries, including agriculture, energy, and manufacturing.

On the other hand, liquid bulk covers goods like oil, chemicals, and liquefied gases, which are pivotal for the chemical and energy sectors. This area of logistics is characterized by its need for specialized vessels, equipment, and handling techniques to move these substantial quantities of goods efficiently and safely across the globe. The essence of bulk cargo logistics lies in its ability to support the global supply chain, facilitating the flow of fundamental commodities that fuel industries and, by extension, economies worldwide.

With its unique set of challenges, including the handling and transportation of such diverse and often hazardous materials, bulk cargo logistics plays a crucial role in maintaining the continuity of trade and industry operations on a global scale.

Bulk cargo logistics plays a critical role in facilitating global trade by enabling the movement of large quantities of essential commodities, such as grains, coal, and oil. This capability is crucial for supporting the industrial supply chains, ensuring the continuous availability of materials necessary for various sectors of the economy. Without the specialized processes of bulk cargo logistics, the transportation of these vital resources would become significantly more challenging and expensive, potentially leading to disruptions in supply and affecting global markets.

Furthermore, by optimizing transportation routes and employing efficient cargo handling methods, bulk cargo logistics contributes to minimizing costs and enhancing the overall efficiency of the global supply chain. It stands as a foundational element in maintaining the smooth operation of international trade and industrial productivity. The significance of bulk cargo logistics extends beyond mere transportation; it is a key enabler of economic stability and growth, highlighting its indispensable role in the world economy.

Bulk cargo logistics acts as a crucial enabler of global trade by efficiently transporting large volumes of essential commodities across international borders. This capability to move vast quantities of goods like grains, coal, and oil is fundamental to connecting producers with global markets. It allows for the seamless exchange of raw materials necessary for various industries, thereby facilitating economic growth and international trade on a scale that would otherwise be unachievable.

Specific Statistics:

In the realm of industrial operations, bulk cargo logistics plays a vital role in maintaining the stability and efficiency of supply chains. It ensures the timely and reliable delivery of critical raw materials and intermediate goods, which are indispensable for continuous production processes. This support is essential for industries to meet consumer demand, manage inventory, and strategize for future developments effectively.

Case Study:

As a result, bulk cargo logistics is not just about transportation; it’s a cornerstone of industrial productivity and economic sustainability, underpinning the seamless flow of commodities that drive global trade and support the intricate web of industrial supply chains.

Bulk cargo is classified into two principal categories: dry bulk cargo and liquid bulk cargo. Dry bulk cargo includes a variety of solid materials such as grains, which are essential for feeding the world’s population; coal, a primary source of energy; and iron ore, the backbone of the steel manufacturing industry. These goods are typically transported in massive quantities, playing a pivotal role in global maritime trade.

Conversely, liquid bulk cargo comprises crucial fluids like oil, the lifeblood of the global economy; chemicals, necessary for a myriad of industrial processes; and liquefied gases, used extensively in energy production and other manufacturing sectors. The safe and efficient movement of these liquids necessitates the use of specialized tankers and stringent handling protocols to prevent spills and contamination. Together, dry and liquid bulk cargoes are indispensable to the logistics sector, enabling the seamless flow of fundamental commodities that fuel international trade and industrial activities.

Dry bulk cargo encompasses essential solid commodities that are foundational to the functioning of global economies. Among these, grains serve as a vital component of the global food supply, essential for feeding the world’s population. Coal, despite the growing emphasis on renewable energy, remains a significant source of energy, powering industries and electricity generation worldwide.

Iron ore is critical for the steel industry, underpinning the construction and manufacturing sectors with the raw material needed for infrastructure and development. The bulk transportation of these goods demonstrates the efficiency and critical nature of dry bulk logistics in facilitating international trade and supporting industrial activities.

Liquid bulk cargo covers a range of liquid commodities that are integral to industrial processes and daily living. Oil, as the mainstay of global energy consumption, fuels transportation, heating, and serves as a key input in the chemical industry. Chemicals, encompassing a broad spectrum from industrial solvents to fertilizers, are indispensable for numerous industrial processes and consumer products.

Liquefied gas, including natural gas and propane, is essential for energy production, heating solutions, and as a critical feedstock for the petrochemical industry. The specialized handling and transportation of these liquids underscore the complexity and essential role of liquid bulk logistics in maintaining the flow of critical resources in the global economy. To provide a clearer understanding of the scale and specifics of these cargo types, the following table outlines the global trade volumes and specific challenges associated with transporting these commodities:

| Cargo Type | Commodities | Global Trade Volume (Annual) | Specific Challenges |

|---|---|---|---|

| Dry Bulk Cargo | Grains, Coal, Iron Ore | Grains: 450 million tons | |

| Coal: 1.1 billion tons | |||

| Iron Ore: 1.5 billion tons | Dust control, moisture management | ||

| Liquid Bulk Cargo | Oil, Chemicals, Liquefied Gas | Oil: 2 billion tons | |

| Chemicals: 250 million tons | |||

| Liquefied Gas: 350 million tons | Temperature control, spill prevention, specialized containment |

Bulk cargo transportation leverages a diversified array of modes, each optimized for the particular characteristics of the cargo it moves. By sea, the backbone of international trade, bulk carriers and tankers are specialized vessels designed to carry vast quantities of dry or liquid commodities, connecting global markets with essential resources. By rail, an efficient conduit for inland transportation, hopper cars and tank cars are utilized for their ability to transport large volumes of bulk materials across continents, providing a vital link from ports to remote inland destinations.

By road, trucks and trailers offer the ultimate in flexibility and reach, ensuring that bulk goods can be delivered directly to where they are needed, from local distribution points to the heart of industrial zones. Together, these transportation methods constitute a robust network, underpinning the seamless flow of bulk cargo around the world and supporting the intricate web of global supply chains.

Transporting bulk cargo by sea relies on the specialized capabilities of bulk carriers for dry commodities and tankers for liquid goods. These vessels are engineered for high capacity and efficiency, crucial for moving large volumes of critical resources such as grains, coal, iron ore for dry bulk, and oil and chemicals for liquid bulk. Maritime transport is a linchpin in connecting global markets, playing an indispensable role in the facilitation of international trade and the equitable distribution of essential commodities across continents.

Notable Vessels and Capabilities:

By rail, bulk cargo finds an efficient passage across vast distances using hopper cars for dry goods and tank cars for liquids. This mode is integral to the supply chain, offering a cost-effective and reliable method for transporting bulk materials from ports to inland destinations. Rail networks serve as a vital artery for the economy, ensuring the steady flow of minerals, agricultural produce, and petrochemicals, and reinforcing the infrastructure necessary for global trade.

Major Rail Networks:

By road, the versatility of trucks and trailers is unmatched in delivering bulk cargo directly to its final destination. This mode is essential for the ‘last mile’ delivery, providing the agility needed to navigate local roads and deliver goods to remote areas. Road transport is key to regional distribution, connecting local markets to the broader global supply chain and ensuring that commodities are available to consumers and industries at the right place and time, thereby maintaining the continuity of economic activities and daily life.

Technology Enhancements:

Transportation Modes and Innovations Table:

| Mode | Vessel/Equipment | Notable Innovations or Examples |

|---|---|---|

| Sea | Bulk Carriers and Tankers | Valemax Bulk Carriers (up to 400,000 DWT), TI Class Supertankers (up to 440,000 DWT) |

| Rail | Hopper Cars and Tank Cars | Union Pacific Railroad (US), Trans-Siberian Railway (Russia) |

| Road | Trucks and Trailers | GPS Tracking for real-time cargo monitoring, Automated Logistics Platforms for optimized route planning and operational efficiency |

The realm of bulk cargo logistics is fraught with challenges that impact the efficiency and sustainability of global supply chains. Environmental regulations stand out as a significant challenge, demanding adherence to strict standards on emissions and spillages. This necessitates a shift towards cleaner, more sustainable operational practices, a task that requires substantial investment and innovation.

Infrastructure limitations at ports and railheads present another hurdle, where inadequate facilities can lead to congestion and delays, adversely affecting the timely delivery of goods. Moreover, safety and handling issues take precedence, especially with the transportation of hazardous materials like chemicals and liquefied gases. These materials require specialized handling and equipment to mitigate risks of accidents and contamination.

Together, these challenges highlight the intricate balance required to navigate the complexities of bulk cargo logistics, underscoring the need for ongoing innovation and strategic planning to maintain the seamless flow of commodities across the globe.

Environmental regulations impose stringent requirements on emissions and spillages, significantly influencing bulk cargo logistics operations. These regulations aim to minimize the environmental footprint of transporting goods, particularly those that could harm air and water quality. Adapting to these mandates necessitates a shift towards greener, more sustainable logistics practices, including the adoption of low-emission transport modes and enhanced spill-prevention technologies.

Key International Regulations:

Facing infrastructure limitations at ports and railheads poses a substantial challenge, directly impacting the flow and efficiency of bulk cargo logistics. Congestion and outdated facilities can lead to considerable delays in cargo handling, disrupting schedules and inflating costs. Addressing these issues requires significant investments in infrastructure upgrades and expansion efforts to enhance capacity and streamline operations.

Recent Infrastructure Projects:

Navigating safety and handling issues is crucial, especially when transporting hazardous materials or goods susceptible to contamination. Implementing rigorous safety protocols, utilizing specialized handling equipment, and providing thorough training are essential measures to prevent accidents, spills, and the contamination of goods. These practices are indispensable for safeguarding human and environmental health.

Statistics on Incidents:

Challenges and Solutions Table:

| Challenge | Specifics | Solutions/Regulations |

|---|---|---|

| Environmental Regulations | IMO 2020 sulfur cap; MARPOL Annex VI | Adoption of low-sulfur fuels; installation of scrubbers |

| Infrastructure Limitations | Panama Canal Expansion; Belt and Road Initiative | Investment in port and rail infrastructure upgrades |

| Safety and Handling Issues | Oil spills (6 large, 4 medium in 2020); Bulk carrier incidents | Strict adherence to safety protocols; specialized training for crew |

Effective management of bulk cargo logistics is underpinned by several critical components that collectively ensure the efficient and reliable movement of goods. Efficient transportation routes stand out as a cornerstone, crucial for minimizing both transit times and operational costs. Strategic planning and optimization of these routes are essential for navigating the intricacies of global trade efficiently.

Cargo handling and storage practices are paramount in safeguarding the cargo’s integrity, necessitating advanced handling techniques and facilities to mitigate the risk of loss or damage. Moreover, regulatory compliance emerges as a fundamental pillar, encompassing adherence to a myriad of international and local standards and laws. This includes strict environmental regulations, safety protocols, and customs procedures, which are vital for smooth and lawful operations.

Together, these components embody the essence of effective bulk cargo logistics management, driving the seamless flow of commodities across the global supply chain.

Efficient transportation routes are essential for minimizing both costs and transit times in bulk cargo logistics. Strategic route optimization is key, enabling the selection of the most direct and cost-effective paths for transporting goods. The use of advanced route optimization software has become increasingly prevalent, leveraging algorithms to analyze various factors such as weather conditions, port congestion, and fuel costs to determine the most efficient routes.

This technology has significantly impacted cost reduction, allowing companies to save on fuel and reduce overall transportation times.

Cargo handling and storage are critical components in preserving the integrity and quality of bulk commodities. Innovations in storage solutions and handling techniques have played a pivotal role in minimizing cargo loss. For example, the development of fully automated bulk material handling systems has reduced human error and improved operational efficiency.

Additionally, the use of sealed and climate-controlled storage facilities has significantly reduced the risk of contamination and spoilage, especially for sensitive commodities like food grains and chemicals. These advancements underscore the importance of adopting modern technologies and practices in maintaining the quality and safety of bulk cargo.

Regulatory compliance stands as a pillar of successful bulk cargo logistics operations. Adherence to a broad spectrum of laws and standards is mandatory to navigate the complex legal landscape of international logistics. High-profile cases of non-compliance have resulted in significant fines or penalties for logistics companies, underscoring the critical nature of compliance.

For instance, in recent years, several shipping companies have faced hefty fines for violating environmental regulations related to sulfur emissions. These cases highlight the potential financial and reputational risks associated with non-compliance, emphasizing the need for logistics operators to stay informed and adhere strictly to all relevant laws and regulations. By focusing on these key components and integrating advanced technologies and best practices, bulk cargo logistics management can achieve greater efficiency, reliability, and compliance, ensuring the smooth and sustainable flow of commodities across the global supply chain.

Technology has been a game-changer in the realm of bulk cargo logistics, significantly enhancing operational efficiency, safety, and environmental sustainability. Automation in cargo handling has not only streamlined processes but also reduced the reliance on manual labor, thereby lowering the chances of human error and enhancing both productivity and safety. Tracking and monitoring systems have ushered in a new era of transparency within the supply chain, providing stakeholders with real-time access to critical data regarding cargo location, condition, and delivery timelines.

This level of visibility is crucial for optimizing logistics operations and improving customer satisfaction. Moreover, data analytics has emerged as a powerful tool for route optimization and strategic decision-making, enabling the analysis of vast datasets to uncover insights that lead to cost savings and service enhancements. Through these technological innovations, bulk cargo logistics has evolved into a more agile, reliable, and robust industry, capable of meeting the dynamic demands of the global market.

Automation in cargo handling has revolutionized efficiency levels in bulk cargo logistics. The introduction of automated systems and robots, such as the Automated Guided Vehicles (AGVs) and robotic arms, into cargo handling operations has significantly minimized the reliance on manual labor. For instance, in major ports, AGVs are used to transport containers from the quay to the yard efficiently, while robotic arms are employed for precision tasks such as unloading bulk materials from ships.

These advancements not only speed up the cargo handling process but also elevate safety standards and operational reliability, leading to enhanced throughput and greater efficiency across the supply chain.

Tracking and monitoring systems have redefined supply chain management within bulk cargo logistics. A notable case study is the implementation of GPS tracking and IoT sensors by a leading logistics company, which dramatically improved the efficiency and security of its bulk cargo operations. The company equipped its fleet with IoT sensors, allowing for real-time monitoring of vehicle locations, cargo conditions, and environmental parameters.

This technology enabled the company to optimize routes, respond proactively to potential issues, and provide customers with up-to-the-minute information on their shipments. The result was a significant reduction in transit times, enhanced cargo security, and increased customer satisfaction.

Data analytics plays a pivotal role in strategic planning in bulk cargo logistics. Leveraging big data, logistics companies can analyze patterns, predict trends, and make informed decisions to optimize operations. For example, by analyzing historical data on weather conditions, port congestion, and shipping routes, companies can identify the most efficient paths for their vessels, reducing fuel consumption and avoiding delays.

Furthermore, predictive analytics can forecast demand fluctuations, enabling companies to adjust their capacities accordingly. These insights not only drive down costs but also enhance service quality, demonstrating how big data is used to predict logistics trends and optimize operations in the dynamic landscape of global trade. By integrating these technological advancements, bulk cargo logistics is set to become even more efficient, responsive, and sustainable, ensuring the seamless flow of commodities across the global supply chain and supporting the intricate web of international trade.

The horizon for bulk cargo logistics is marked by significant shifts towards sustainability, technological advancement, and the seamless integration of digital solutions. A paramount trend is the industry-wide pivot towards sustainability practices, aiming to mitigate environmental impacts through cleaner energy use and route optimization. This shift not only addresses ecological concerns but also aligns with global efforts to combat climate change.

The increased use of IoT and AI technologies heralds a new era of efficiency and transparency within logistics operations. These innovations facilitate enhanced tracking capabilities, predictive analytics for maintenance, and superior route optimization, paving the way for smarter, more informed logistics strategies. Additionally, the growth of intermodal transportation solutions underscores a move towards greater flexibility and efficiency in logistics.

By leveraging the strengths of various transport modes, these solutions offer a way to streamline operations, reduce costs, and minimize environmental footprints. Collectively, these trends forecast a future where bulk cargo logistics is not only more sustainable and efficient but also increasingly adaptive to the dynamic demands of the global marketplace.

Sustainability practices are at the forefront of transforming bulk cargo logistics into a more environmentally friendly sector. Embracing renewable energy, optimizing transportation routes for maximum fuel efficiency, and adopting measures to significantly reduce carbon footprints are all part of this green shift. These initiatives not only align with global environmental efforts but also meet the growing demands from consumers and regulatory bodies for sustainable supply chain practices.

The push towards greener operations in logistics signals a deep-rooted commitment to preserving the environment while maintaining economic and operational effectiveness.

The increased use of IoT (Internet of Things) and AI (Artificial Intelligence) is revolutionizing bulk cargo logistics by ushering in an era of smart logistics. IoT-enabled devices facilitate unparalleled real-time tracking and environmental monitoring of shipments, while AI provides predictive analytics for maintenance, optimizes routes, and forecasts demand with high accuracy. This synergy of cutting-edge technologies fosters a more intelligent, efficient, and proactive logistics landscape, characterized by data-driven decision-making and minimized risks.

The adoption of IoT and AI technologies is pivotal in transforming logistics operations into agile, responsive systems capable of navigating the complexities of modern supply chains.

The growth of intermodal transportation solutions highlights a significant trend towards more flexible and efficient logistics strategies. Integrating various modes of transport—such as combining rail, road, and maritime transport—offers a cohesive approach to moving cargo. This strategy not only leverages the unique advantages of each transportation mode but also aligns with sustainability objectives by minimizing the environmental impact.

The rising popularity of intermodal solutions underscores their ability to offer cost savings, operational flexibility, and eco-friendly benefits, marking a shift towards more sustainable and adaptable logistics practices.

Vessels undergo rigorous inspections to ensure compliance with Grain Clean Vessel Standards, starting with a pre-loading inspection. This step evaluates cargo holds for cleanliness and suitability, focusing on eliminating previous cargo residues, pests, and ensuring adequate ventilation. Continuous monitoring during loading ensures operational practices adhere to the standards. Certified inspectors or appointed surveyors from relevant regulatory bodies conduct these inspections, guaranteeing vessels meet the requirements for safe and efficient grain transport.

Pre-loading inspection assesses the cleanliness and suitability of the vessel’s cargo holds, ensuring no residues from prior cargoes, no pests, and functional ventilation systems to prevent moisture and mold. This step safeguards the grain’s integrity, preparing the vessel for safe transport.

Continuous monitoring during loading ensures operational practices align with Grain Clean Vessel Standards, maintaining the cleanliness and safety protocols established during pre-loading. It involves vigilant observation of how grain is handled and stowed, securing the cargo’s quality and safety from loading to delivery.

| Inspection Stage | Criteria | Methods/Tools Used | Description |

|---|---|---|---|

| Pre-loading Inspection | Cleanliness | Visual inspection, UV lights | Checking for visible residues, signs of previous cargo, and ensuring no visible pests or signs of infestation. |

| Pest Infestation | Pest traps, Visual inspection | Looking for signs of pests, including droppings, damage, or live insects. | |

| Ventilation | Ventilation system check | Ensuring ventilation systems are operational and adequate for the cargo type. | |

| Moisture Levels | Moisture meters, Hygrometers | Measuring humidity and moisture content within the cargo hold to prevent mold growth. | |

| Continuous Monitoring | Operational Practices | Checklist, Real-time monitoring systems | Observing the loading process, ensuring grain is handled properly and cleanliness is maintained. |

| Cargo Integrity | Visual inspection, Sampling | Regular checks on grain condition during loading to ensure no contamination occurs. | |

| Safety Protocols | Safety audit, Checklist | Ensuring all safety measures are followed during loading, including PPE usage and adherence to emergency procedures. |

This detailed approach ensures vessels meet Grain Clean Vessel Standards from the outset and maintain these standards throughout loading, safeguarding grain cargo quality and safety.

For a vessel to qualify as grain clean, it must meet criteria ensuring grain safety and quality during transport. These criteria include:

Adhering to these criteria is fundamental for vessels to comply with Grain Clean Vessel Standards, ensuring they are prepared to transport grain cargoes safely and efficiently.

| Criterion | Acceptable Condition | Unacceptable Condition | Examples/Notes |

|---|---|---|---|

| Absence of previous cargo residues | No visible residues or odors present in the cargo holds. | Any visible residues, stains, or odors from previous cargoes. | Residues might include grains, powders, or oils from previous cargoes. Cleaning must ensure removal of all such traces. |

| No pest infestation | No signs of pests, including insects, rodents, or birds, within the cargo holds. | Any evidence of pest presence or damage caused by pests. | Regular pest control measures should be in place to maintain a pest-free environment. |

| Adequate ventilation | Ventilation systems are operational, providing sufficient airflow to prevent moisture buildup. | Blocked, damaged, or inadequate ventilation systems leading to high humidity levels. | Proper ventilation is crucial to prevent mold and mildew, which can spoil the grain. |

Ensuring the absence of previous cargo residues is critical for preventing cross-contamination. Residues from prior cargoes can carry contaminants that pose a serious risk to grain quality. A vessel must be meticulously checked to ensure no pest infestation is present, protecting the grain’s integrity. Adequate ventilation in the cargo holds prevents moisture accumulation and mold growth, safeguarding the grain’s quality during its voyage.

Effective hold cleaning procedures prepare a vessel for grain transport, ensuring it meets Grain Clean Vessel Standards. These procedures involve steps to create a contaminant-free environment for the grain cargo. The process begins with initial sweeping and residue removal, effectively clearing the hold of any remnants from previous cargoes.

Following this, washing down with high-pressure water removes lingering particles, ensuring a thorough cleanse. For more persistent stains or residues, chemicals may be necessary. Ensuring the holds are dry and odor-free establishes ideal conditions for safe grain transport.

Adherence to these detailed cleaning procedures is essential for preventing contamination and maintaining grain quality during transport.

The cleaning process begins with initial sweeping and removal of residues, clearing the cargo holds of any detritus from past cargoes. This step eliminates potential contamination sources early in the cleaning procedure, laying the groundwork for a comprehensive cleanse.

After sweeping, the holds are washed down with high-pressure water. This technique ensures remaining particles are flushed away. High-pressure washing is effective in cleaning hard-to-reach areas, reducing contamination risk and preparing the surface for additional cleaning if needed.

When residues are tenacious, chemicals are used. Selected for efficacy, these cleaning agents break down and remove stubborn stains, ensuring the hold meets the highest cleanliness standards for grain transport.

The final step is ensuring the holds are dry and odor-free. Moisture and odors can indicate mold or bacterial growth, posing a risk to grain quality. Achieving a dry, neutral-smelling hold is imperative for safe grain transport.

| Cleaning Step | Actions/Techniques | Recommended Cleaning Agents/Equipment |

|---|---|---|

| Initial Sweeping and Removal of Residues | Manual sweeping and vacuuming of all accessible areas | N/A |

| Washing Down with High-Pressure Water | Use of high-pressure hoses to wash down surfaces | N/A |

| Use of Chemicals for Stubborn Stains | Application of chemical agents to affected areas | Solvent-based cleaners for oil residues, Acidic cleaners for rust and scale, Alkaline cleaners for organic residues |

| Ensuring Dry and Odor-Free Holds | Ventilation and use of dehumidifiers | Industrial dehumidifiers, Air movers for enhanced ventilation |

This comprehensive approach ensures cargo holds meet the rigorous standards required for safe grain transport.

Non-compliance with Grain Clean Vessel Standards can have severe repercussions for shipping companies and cargo owners. Primary consequences include cargo rejection at the destination port, leading to financial losses and logistical complications. Financial penalties may also be imposed by regulatory bodies, adding to the economic burden of non-compliance.

In severe cases, vessels consistently failing to meet cleanliness and safety criteria might face bans from certain ports, significantly impacting operational capabilities and tarnishing their reputation. These consequences highlight the critical importance of strict adherence to Grain Clean Vessel Standards to ensure safe, efficient grain transport.

Cargo rejection at the destination results in significant financial loss. This situation arises from return or disposal costs and the loss of goods. For example, in 2018, a vessel carrying wheat from the United States to Brazil was rejected due to live insects, leading to losses exceeding $2 million for the shipping company. Such setbacks underscore the importance of adhering to cleanliness and safety standards.

Non-compliance may trigger financial penalties from regulatory bodies, adding a financial burden beyond cargo rejection losses. Fines can range from tens of thousands to hundreds of thousands of dollars, depending on the non-compliance severity and jurisdiction involved.

Repeated non-compliance can lead to port bans, severely impacting operational flexibility and tarnishing the shipping company’s reputation. For example, a series of non-compliance incidents in 2017 led to a bulk carrier being banned from Australian ports for 12 months, significantly affecting the shipping company’s operations in a key market for grain export.

Ensuring compliance with Grain Clean Vessel Standards requires a comprehensive approach, starting with developing and adhering to a Hold Preparation Checklist. This checklist acts as a roadmap for cleaning and inspection, guaranteeing all criteria are addressed before loading grain. Regular vessel maintenance preemptively addresses issues that could compromise cargo integrity and ensures ongoing cleanliness.

Employing certified cleaning services with grain standards experience offers specialized expertise, ensuring vessels meet rigorous requirements. Training the crew on standards and procedures empowers them to identify and address compliance issues. These strategies create a solid foundation for maintaining high standards for grain transport.

A Hold Preparation Checklist is an indispensable guide, detailing steps for thorough cleaning and inspection of cargo holds. This comprehensive checklist ensures a methodical approach to meeting Grain Clean Vessel Standards, covering everything from residue removal to ensuring proper ventilation, facilitating meticulous verification.

Regular vessel maintenance is crucial for upholding cleanliness standards. Systematic inspections and upkeep preemptively address conditions compromising grain cargo integrity. This continuous maintenance regime keeps vessels in prime condition, ready for safe grain transport.

Hiring certified cleaning services specializing in grain standards brings expertise and efficiency critical for compliance. These professionals possess the knowledge, experience, and equipment to clean cargo holds according to Grain Clean Vessel Standards, ensuring an expertly managed cleaning process.

Training the crew on grain transport standards and procedures ensures compliance. This training equips crew members with the knowledge to implement cleanliness and safety protocols, fostering a culture of vigilance and responsibility supporting Grain Clean Vessel Standards maintenance aboard the vessel.

| Compliance Aspect | Details | Examples/Actions |

|---|---|---|

| Hold Preparation Checklist | Removal of previous cargo residues | Visual inspection for cleanliness |

| Pest control measures | Application of pest control treatments | |

| Ventilation check | Testing ventilation systems for proper airflow | |

| Regular Vessel Maintenance | Hold framing and bulkhead coatings | Checking for corrosion |

| Hatch covers, trackways, and vents | Sealing integrity checks | |

| Tank top and double bottom lid maintenance | Inspection for rust and scale | |

| Bilge well and system maintenance | Testing bilge pumps | |

| Training for Crew | Standards and procedures for grain transport | Grain Clean Vessel Standards overview |

| Use of cleaning equipment and chemicals | Training on safe and effective use of cleaning agents and equipment | |

| Pest control measures | Identification and application of approved pest control methods | |

| Emergency procedures for contamination prevention | Response strategies for pest infestation |

The Master of a vessel holds crucial responsibilities for ensuring grain cleanliness, including clarifying cleaning instructions, overseeing the Hold Cleaning Schedule and Progress, and maintaining records and communication with charterers. These duties are essential for upholding Grain Clean Vessel Standards and protecting grain cargo.

The Master must provide the crew with clear, detailed cleaning instructions to ensure all protocols are correctly executed, reducing contamination risk.

The Master oversees the Hold Cleaning Schedule and Progress, ensuring cleaning operations align with standards and timelines, readying the vessel for grain loading.

The Master maintains meticulous records of cleaning activities and outcomes and communicates transparently with charterers about the vessel’s readiness and compliance.

The Deck Officer of the Watch or Cargo Officer ensures the vessel adheres to Grain Clean Vessel Standards, overseeing ballasting and cleaning operations and ensuring compliance during loading. Best practices and common challenges are highlighted to provide a comprehensive overview.

The Deck Officer of the Watch/Cargo Officer monitors ballasting and cleaning operations, ensuring practices align with cleanliness and safety protocols.

Ensuring compliance during loading involves overseeing grain handling and maintaining vessel integrity against contamination.

Effective hold maintenance is crucial for safe grain transport, requiring strict compliance with Grain Clean Vessel Standards. Below are key maintenance practices, inspection frequencies, and common repairs needed.

What are Grain Clean Vessel Standards?

Grain Clean Vessel Standards refer to the regulatory guidelines ensuring vessels used for transporting grain maintain a level of cleanliness to prevent contamination and preserve the quality of the grain during transit.

Why are Grain Clean Vessel Standards important?

These standards are crucial for protecting the integrity of grain shipments, preventing the spread of pests and diseases, and ensuring that recipients receive high-quality, uncontaminated grain products.

How are Grain Clean Vessel Standards enforced?

Enforcement typically involves inspections and certifications by agricultural and maritime authorities. Vessels must pass rigorous checks for cleanliness and suitability for grain transport before loading.

What happens if a vessel fails to meet the Grain Clean Vessel Standards?

Failure to meet these standards can result in the vessel being denied loading until it passes a thorough cleaning and inspection process, ensuring compliance with the required cleanliness levels.

Can Grain Clean Vessel Standards vary by country?

Yes, while there are international guidelines, individual countries may impose additional requirements based on local agricultural regulations and standards to further protect their grain industries.