Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

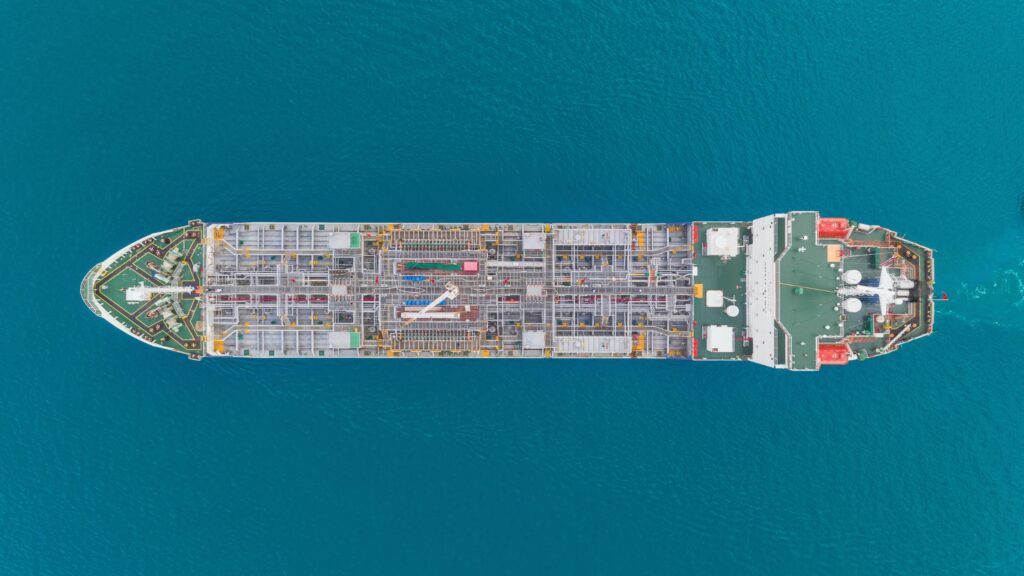

Bulk carriers play a crucial role in the shipping industry due to their robust capacity and versatility. These vessels are engineered to transport unpackaged bulk cargo, such as grains, coal, and minerals, in vast holds. Their importance in the global supply chain is unmatched, making them essential for moving raw materials worldwide.

Different types of bulk carriers, from Handysize to Capesize, are designed for specific trades, offering a range of sizes and capabilities to meet various demands. Single Grain Bulk carriers, for instance, cater to lighter yet bulkier cargoes with their expansive storage spaces. The design, operational techniques, and safety measures of bulk carriers involve complex maritime engineering and logistics.

The hull structures, loading, and unloading operations require precision and contribute to the efficiency and safety of bulk carriers at sea. The following sections will delve into these aspects, providing insights into the vital role bulk carriers play in global trade.

Bulk carriers are specialized ships designed to transport vast quantities of unpackaged bulk cargo, such as grains, coal, ore, and cement. These vessels stand out for their large hatches and deep holds, which are engineered for efficiency and safety, catering specifically to the bulk commodity trading market. The design of a bulk carrier is meticulously planned to maximize cargo space and facilitate easy loading and unloading, taking into account the cargo’s weight and properties to influence the vessel’s overall structure.

Safety is of paramount importance in the operation of bulk carriers, with stringent regulations in place to prevent structural failures and ensure the safety of both the crew and the marine environment. The routes and ports frequented by bulk carriers are strategically chosen to link major exporters and importers across continents, reflecting the global nature of the commodity trade. Bulk carriers are indispensable to the shipping industry, playing a crucial role in the global supply chain by enabling the seamless movement of essential raw materials.

These vessels support various sectors of the economy, making them a cornerstone in the world of maritime trade.

Bulk cargo is divided into dry bulk cargo and liquid bulk cargo.

Each type of bulk cargo requires distinct handling, storage, and transport techniques, reflecting the diverse nature of goods moved across the global maritime network.

The design and structure of bulk carriers are tailored for the efficient and safe conveyance of bulk cargo. Key features include large cargo holds and wide hatches to streamline the loading and unloading process. The vessel’s hull is segmented into compartments or holds, reinforced to bear substantial weights and reduce the risk of structural failure.

Many bulk carriers are equipped with cargo handling gear, such as cranes and conveyors, for self-loading and unloading, though they often rely on port infrastructure. Crucial to their design is the ballast system, vital for ensuring stability during transit.

The loading and unloading methods for bulk carriers vary with the cargo type and port facilities. Dry bulk cargo is generally loaded via chutes or conveyors, which directly transfer the cargo into the ship’s holds, while liquid bulk cargo is pumped into tankers. For unloading, equipment like cranes, grabs, and pumps are used, depending on the cargo.

Some advanced bulk carriers feature self-unloading technologies, including conveyor belts and vacuum systems, to enhance efficiency in cargo discharge.

The methods for loading and unloading bulk carriers vary depending on the type of cargo and the facilities available at ports:

Self-unloading bulk carriers have integrated systems, such as conveyor belts or vacuum systems, to streamline cargo discharge without needing extensive port infrastructure.

Safety considerations for bulk carriers cover various aspects to prevent structural issues, cargo shifts, and environmental impacts. Key safety measures include:

Safety considerations for bulk carriers encompass a broad spectrum, aimed at averting structural issues, cargo shifts, and environmental impacts. The International Maritime Organization (IMO) enforces global standards, such as the International Bulk Chemical Code (IBC Code) and the International Safety Management (ISM) Code, to promote the safe operation of these vessels.

The major routes and ports for bulk carriers are shaped by the international trade of bulk commodities. Prominent routes include the iron ore shipments from Australia to China, coal transport from South Africa to Europe, and grain deliveries from North America to Asia. Significant bulk ports such as Port Hedland in Australia, Rotterdam in the Netherlands, and Qingdao in China are pivotal, equipped with specialized infrastructure to manage the substantial volumes of bulk cargo.

These routes and ports play a critical role in the efficiency of global supply chains, facilitating the continuous movement of essential commodities worldwide.

Container ships are designed to carry goods in standardized shipping containers. This method offers a versatile and efficient way to transport a wide range of products worldwide. Container ships vary in size, from small coastal feeders to immense Ultra Large Container Vessels (ULCVs) that navigate major trade routes. They are engineered to maximize cargo capacity, safety, and operational efficiency.

The containers are securely stowed in the ship’s hold and on deck, locked in place by cell guides, ensuring stability and safety during transit. The introduction of containerization has revolutionized the shipping industry, streamlining the loading and unloading process through coordinated port operations, drastically cutting down on shipping times and costs. Operating on fixed routes between key port cities, container ships offer predictable and reliable service, essential for shippers worldwide.

This intricate global network underpins international commerce, playing a pivotal role in maintaining the flow of goods in the worldwide supply chain.

Container ships utilize a variety of standardized shipping containers to transport goods, catering to diverse cargo requirements. The industry primarily uses the 20-foot Equivalent Unit (TEU) and the 40-foot Equivalent Unit (FEU) as standard measurements for container ship capacity. To address specific cargo needs, specialized containers like refrigerated containers (reefers) for perishables, open-top containers for tall items, and tank containers for liquids are employed, ensuring the safe and efficient movement of a wide array of goods.

The efficiency of container shipping heavily relies on specialized container handling equipment. Gantry cranes play a pivotal role, lifting containers on and off the ships at ports. For the movement and stacking of containers within terminals, straddle carriers and reach stackers are indispensable.

Additionally, automated guided vehicles (AGVs) and terminal tractors facilitate the transport of containers between the quay and storage areas, streamlining operations within the port.

The global trade network is supported by container ships navigating through common shipping routes that link the world’s major port cities. Key routes include the Asia-Europe route, which passes through the Suez Canal; the Trans-Pacific route, connecting Asia with North America; and the Trans-Atlantic route, bridging North America and Europe. These routes are served by liner services, offering scheduled sailings and fixed itineraries, providing shippers with dependable and predictable options for transporting goods.

The operational efficiency and reliability of these services are fundamental to the smooth functioning of international trade.

Tankers are specialized vessels engineered for the transportation of liquid cargoes, crucial for the global distribution of vital commodities such as crude oil, refined petroleum products, chemicals, and liquefied natural gas (LNG). These vessels vary significantly in size and design, each tailored to meet the specific requirements of the liquid cargo they transport. From the colossal VLCCs (Very Large Crude Carriers) and ULCCs (Ultra Large Crude Carriers), which ferry crude oil across the seas, to the smaller, more specialized chemical tankers that distribute a variety of chemical products, tankers are a cornerstone of the maritime industry.

The design of tankers prioritizes safety and environmental protection, featuring double hulls and advanced containment systems to mitigate the risk of spills. Operating along global routes, these vessels form the lifelines connecting oil fields, refineries, and consumer markets. Subject to rigorous international regulations, tanker operations are closely monitored to ensure they adhere to the highest standards of safety and eco-friendliness.

The ability of tankers to efficiently transport large volumes of liquid cargo is indispensable to the energy sector and the broader economy, maintaining the continuous flow of materials essential for powering industries and fueling transportation networks around the world.

Oil tankers are specialized vessels tasked with the transportation of oil and its derivatives worldwide. They range in size from smaller coastal tankers to the enormous VLCCs (Very Large Crude Carriers) and ULCCs (Ultra Large Crude Carriers), pivotal for moving crude oil from drilling sites to refineries, and refined products to consumer markets. These tankers are built with double hulls and incorporate advanced safety mechanisms to mitigate environmental risks, ensuring the secure transit of this vital energy commodity.

Oil tankers are indispensable to maintaining the global energy supply chain, enabling the continuous flow of oil to satisfy the world’s energy needs.

Chemical tankers are vessels specifically designed for the safe transport of various chemical substances, ranging from industrial chemicals to edible oils. These tankers feature specialized tanks and sophisticated handling systems to accommodate the diverse and often hazardous nature of chemical cargoes. Emphasizing safety and environmental protection, chemical tankers operate under strict regulations that dictate their construction and operation.

Their advanced designs facilitate the safe separation and contamination-free delivery of different chemicals, underlining their efficiency and importance in the chemical trade.

LNG carriers are specialized ships designed for the transport of liquefied natural gas at cryogenic temperatures (-162°C), featuring highly insulated tanks to maintain the gas in its liquid state. These carriers are pivotal in the global energy landscape, allowing for the transport of natural gas from isolated production fields to markets worldwide, where it is regasified and distributed. The evolution of the LNG industry has spurred innovations in carrier design, notably the development of Q-Flex and Q-Max vessels, which represent some of the largest LNG carriers in operation, offering enhanced efficiency and a reduced environmental footprint.

General cargo ships are versatile vessels engineered to transport a diverse array of goods that do not fit the specific requirements of bulk or container ships. These vessels are capable of carrying break bulk, heavy lift, and project cargoes, offering flexibility to accommodate a variety of cargo types within a single voyage. Their adaptability extends to loading and unloading methods, making them particularly suited for ports with limited or no specialized cargo handling infrastructure.

General cargo ships are characterized by their multiple decks and equipped with strong cranes, facilitating the handling of different sizes and weights of cargo. They are indispensable in global trade, especially for routes or regions less served by containerization, providing vital logistics solutions across industries.

Break bulk ships specialize in the transportation of non-containerized cargo, handling goods individually, such as bags, barrels, boxes, and drums. These vessels are crucial for cargoes that are unsuitable for container shipping due to their size, shape, or specific handling needs. Equipped with onboard cranes and gear, break bulk ships offer versatility in managing diverse cargo types.

They play an essential role in the logistics chain, catering especially to the shipment needs of machinery, construction materials, and other oversized or heavy commodities.

Multipurpose vessels represent a class of general cargo ships designed with the flexibility to transport a mix of cargo types, including containerized goods, break bulk, and heavy lift items, within a single voyage. Featuring adjustable decks and sophisticated cargo handling systems, these vessels adapt readily to varying cargo specifications, responding efficiently to fluctuating market demands. Their capability to serve ports with limited facilities makes them invaluable for connecting a broad spectrum of industries to the global supply chain.

Heavy lift vessels are tailored for the transport of exceptionally heavy or oversized cargoes with a higher dead weight (DWT) capacity than ordinary vessels, beyond the capacity of conventional shipping methods. These ships boast powerful cranes and reinforced decks to accommodate the unique demands of large machinery, industrial components, and maritime structures. Serving industries such as oil and gas, renewable energy, and construction, heavy lift vessels are pivotal in facilitating the global movement of project cargoes, essential for infrastructure development and large-scale industrial projects across the globe.

Roll-on/Roll-off ships, or Ro-Ro ships, are specialized vessels engineered for the transport of wheeled cargo, such as cars, trucks, trailers, and railroad cars. These vessels are distinguished by their built-in ramps, enabling cargo to be “rolled on” at the source and “rolled off” at the destination, significantly reducing loading and unloading times. Ro-Ro ships present a key advantage for the transportation of vehicles and heavy machinery, offering a secure and cost-efficient shipping solution.

Designed to optimize space and ensure the safe stowage of cargo during sea voyages, Ro-Ro ships are essential to the global trade and logistics sectors, especially pivotal for the automotive industry and other fields that depend on the mass movement of rolling stock and heavy equipment.

Vehicle carriers, a specialized type of Roll-on/Roll-off (Ro-Ro) ships, are dedicated to the transportation of vehicles such as cars, trucks, and heavy machinery worldwide. These carriers boast multiple decks and sophisticated adjustable ramps designed to maximize vehicle capacity, ensuring efficient space utilization and streamlined loading and unloading processes. Vehicle carriers stand as pivotal players in the automotive industry, enabling the swift international movement of new and used vehicles and reinforcing the backbone of global trade networks.

Reefer ships, or refrigerated cargo ships, are specialized vessels tailored for the transport of perishable goods under controlled temperatures. These vessels are indispensable to the global food supply chain, facilitating the movement of temperature-sensitive products such as fruits, vegetables, meat, and dairy products across the oceans. Equipped with sophisticated refrigeration systems, reefer ships maintain precise temperature conditions throughout the journey, ensuring perishables reach their destination in prime condition.

They are pivotal in connecting producers with international markets, supporting the trade of fresh and frozen commodities, and satisfying global demand for out-of-season and exotic foods.

Reefer ships are tasked with the transportation of a broad spectrum of refrigerated cargo, essential to the global food supply chain. They handle fresh fruits and vegetables, maintaining their freshness with precise temperature control during transit. Meat and dairy products, requiring strict temperature management to prevent spoilage, are also key cargoes.

Furthermore, reefer ships transport frozen commodities, including seafood, ice cream, and prepared meals, preserving them in optimal conditions until they reach their destinations. The ability of reefer ships to cater to the varied temperature sensitivities of these perishable goods underscores their vital role in facilitating international trade.

Equipped with advanced temperature control systems, reefer ships ensure the precise management of conditions required by different types of refrigerated cargo. These systems enable the maintenance of temperatures ranging from chilled to deep-frozen, accommodating the specific needs of each cargo type. Central to their operation are sophisticated monitoring and control mechanisms that allow for real-time adjustments, guaranteeing consistent temperature levels throughout the journey.

Additionally, cutting-edge controlled atmosphere technology is employed in some vessels, fine-tuning oxygen and carbon dioxide levels within cargo holds to extend the shelf life of perishables like fruits and vegetables. These comprehensive temperature control systems play a crucial role in preserving the quality and safety of perishable commodities during maritime transport.

Livestock carriers are specialized vessels tailored for the transportation of live animals across oceans. These ships serve as a vital component of the global agricultural supply chain, enabling the movement of livestock such as cattle, sheep, and goats from breeders to markets and farms around the world. Designed with the animals’ well-being in mind, livestock carriers are outfitted with advanced ventilation systems, water supplies, and adequate space for movement and rest, ensuring the safety and comfort of the animals throughout their journey.

The operation of these vessels adheres to stringent international regulations and standards, promoting humane treatment and minimizing stress on the animals. Livestock carriers underscore their importance in the agricultural sector by facilitating the ethical and efficient transport of animals to satisfy the demands of global markets.

The design and layout of livestock carriers are intricately tailored to ensure the health and welfare of the animals during their journey. These ships feature adjustable multi-deck systems to accommodate various livestock types and sizes, providing sufficient space for each animal. Essential design elements include advanced ventilation systems for optimal air quality and temperature control, non-slip flooring to enhance safety, and segregated areas for effective management of different species and sizes, ensuring compatibility and reducing stress.

Integrated watering and feeding systems are critical to sustain hydration and nutrition, while the overall structure supports easy access and movement for animals, crew, and onboard veterinarians, creating a secure and stress-minimized environment.

Animal welfare on livestock carriers is regulated by stringent international standards, including those set forth by the International Convention for the Safety of Life at Sea (SOLAS) and the World Organisation for Animal Health (OIE) Guidelines. These regulations dictate comprehensive requirements for space, ventilation, nourishment, and medical care, aiming to safeguard the animals’ well-being throughout transit. Carriers must undergo rigorous inspections and obtain certifications confirming adherence to these welfare conditions.

The objective is to ensure animals are transported under humane conditions, minimizing stress and discomfort to uphold ethical treatment standards.

Loading and transport procedures on livestock carriers are meticulously organized to facilitate a calm and efficient process for moving animals onto and within the vessel. Initiating with a thorough pre-loading health inspection, the approach ensures animals are fit for travel. During loading, livestock are carefully led onto the ship via specially designed ramps, minimizing stress and risk of injury.

Animals are then allocated to designated areas, sorted by species, size, and health, with a keen focus on meeting space requirements and ensuring compatibility. Throughout the voyage, dedicated crew members and veterinarians continuously monitor the animals, providing necessary care, feed, and water. These procedures are fundamental in maintaining optimal animal welfare from the point of departure to the final destination.

Offshore Supply Vessels (OSVs) are specialized ships tailored for the support of offshore oil rigs, platforms, and other structures within the offshore oil and gas sector. These vessels are pivotal in maintaining the logistical operations of the offshore industry, delivering essential equipment, supplies, and personnel to remote offshore sites. Capable of transporting a diverse array of cargo, including drilling fluids, production chemicals, pipes, and food, OSVs also facilitate the movement of workers to and from offshore locations.

Designed to withstand challenging marine environments, these vessels are equipped with dynamic positioning systems to maintain proximity to offshore facilities without the need for anchoring. OSVs play a vital role in the exploration, development, and upkeep of offshore oil and gas fields, contributing significantly to the continuity and efficiency of global energy production.

Offshore Supply Vessels (OSVs) include a diverse fleet of specialized ships, each designed for particular tasks within offshore operations. Platform Supply Vessels (PSVs) are tasked with delivering essential supplies and equipment, ranging from drilling fluids to construction materials, directly to offshore platforms. Anchor Handling Tug Supply (AHTS) vessels stand out for their strength, managing the deployment and retrieval of anchors for drilling rigs and offering towing services.

Emergency Response and Rescue Vessels (ERRVs) are dedicated to safeguarding offshore operations, equipped for emergency rescue and safety missions. Additionally, Crew Boats and Fast Supply Vessels (FSVs) specialize in the rapid transportation of personnel, ensuring swift and efficient movement between the shore and offshore sites. This variety of OSVs underscores their critical role in the seamless and safe execution of offshore oil and gas operations.

Offshore Supply Vessels (OSVs) deliver a comprehensive suite of functions and services crucial to the offshore oil and gas sector. They provide logistical support by transporting necessary supplies like fuel, water, food, and specialized equipment for drilling and production processes. In the realm of construction and maintenance, OSVs contribute significantly with anchor handling, towing, and the precise positioning of drilling rigs and platforms.

Their role extends to safety and emergency response, with vessels outfitted for search and rescue operations, pollution control, and firefighting, ensuring the well-being of offshore operations and personnel. Crew transport services facilitated by these vessels are essential for the efficient and safe conveyance of workers to and from offshore locations. Collectively, these services ensure the operational continuity and safety of offshore energy projects.

Passenger cargo ships are versatile vessels that serve the dual purpose of transporting both passengers and goods, providing a critical service that caters to a wide range of logistical requirements. These ships play a key role in linking remote communities, particularly in areas where other forms of transportation are scarce or unavailable. Equipped with specialized cargo areas and accommodations for passengers, they facilitate the movement of essential items, mail, and individuals between islands and along coastal routes.

The operation of passenger cargo ships is essential for supporting local economies and enabling international trade, ensuring a continuous exchange of commerce and connectivity. Their multifunctional nature positions them as a valuable asset within the maritime industry, seamlessly integrating the functionalities of traditional cargo transport with passenger ferry services.

Ferry services are a vital component of transportation, offering scheduled routes that transport passengers, vehicles, and cargo across waterways. These services bridge the gap between islands and mainland areas or connect two separated landmasses, playing a crucial role in daily commutes, tourism, and the movement of goods in areas where direct land routes are not available. Ferries range from small boats to large vessels equipped to carry hundreds of passengers and a significant number of vehicles, facilitating economic activities and enhancing accessibility to isolated regions.

Cargo handling on passenger ships is executed with precision to ensure that goods are transported safely and efficiently alongside passengers. Designated cargo areas or containers are used to store goods securely, maintaining a separation from passenger facilities for safety and convenience. The use of roll-on/roll-off (Ro-Ro) systems facilitates the smooth loading and unloading of vehicles and large items, optimizing the process for minimal delays.

A key focus is placed on securing cargo to prevent movement during the voyage, safeguarding the well-being of the cargo and ensuring passenger comfort throughout the journey.

The safety regulations governing passenger cargo ships are rigorous and detailed, aiming to safeguard passengers, crew, and cargo. Overseen by international entities like the International Maritime Organization (IMO), these regulations are encapsulated in conventions such as SOLAS (Safety of Life at Sea) and MARPOL (Prevention of Pollution from Ships). They encompass a wide array of safety measures, including life-saving equipment, fire protection protocols, and safety management systems.

Regular inspections and certifications are mandatory to confirm compliance, with a focus on hull integrity, navigational safety, and emergency response capabilities. Adherence to these stringent safety standards is essential for the operational integrity of passenger cargo ships.

Barge carriers are specialized maritime vessels designed to transport barges, playing a pivotal role in the “Lash” (Lighter Aboard Ship) system or similar methodologies. This innovative approach significantly enhances the efficiency of moving goods by allowing barges to be directly loaded onto a larger ship. Such carriers are instrumental in shipping a diverse array of cargo, including bulk commodities, containers, and oversized items across extensive sea routes.

Offering a flexible and cost-effective shipping solution for bulk cargo, barge carriers merge the inland navigability of barges with the oceanic reach of larger vessels. This synergy greatly improves the connectivity between inland waterways and the open sea, broadening the scope of global trade networks. By facilitating the seamless transfer of cargo from local distribution centers to international markets, barge carriers are essential to the logistics and transportation sector, optimizing cargo delivery and reducing handling requirements.

The LASH (Lighter Aboard Ship) system represents a groundbreaking approach in maritime logistics, seamlessly blending the functionality of barges with ocean-going ships. This system involves loading cargo-laden barges (lighters) onto a specially designed mother ship using cranes. These barges can then be directly offloaded at the destination port and navigate to inland waterways or docks, enabling efficient direct delivery of goods.

The LASH system’s modular nature offers exceptional flexibility and efficiency in cargo handling, accommodating a diverse range of cargo types without reliance on extensive port infrastructure, thereby significantly enhancing the global supply chain’s effectiveness.

The Seabee system offers a unique solution in maritime cargo transport, leveraging a float-on/float-off mechanism that distinguishes it from the crane-dependent LASH system. It employs self-sustaining cargo barges that are floated onto and off the carrier vessel, allowing for operation in a wider variety of port conditions without the need for specialized crane facilities. This system is particularly adept at handling heavy and oversized cargoes, providing a versatile method for transporting large, cumbersome items that pose challenges for traditional shipping approaches.

The Seabee system highlights the adaptability of barge carrier operations to meet specific logistical needs within the maritime transport sector.

Barges are ingeniously designed for stability and capacity, featuring a flat-bottomed structure optimal for transporting goods through rivers, canals, and coastal waters. Their utility spans a wide array of cargo types, from bulk materials like coal and grains to oversized industrial equipment. Barges are categorized into covered, open, and tank types, each suited to particular cargo requirements—covered barges for weather-sensitive goods, open barges for bulk commodities, and tank barges for transporting liquids.

Beyond cargo transport, barges fulfill roles in floating storage, accommodations, and serve as platforms for construction and dredging projects. The multifaceted design and applications of barges underscore their indispensable contribution to the multimodal transport chain, bolstering the efficiency and expansiveness of global logistics networks.